Coating of small parts without hooks |

|

Three different processes |

|

|

In this context, small parts ( work-pieces ) are understood to be in the size of 10 – 100 mm ( 3/8 to 4 inches ). Small parts can be coated basically by 3 completely different coating processe, when large quantities ( millions ) are involved, known also under the designation bulk ware :

- by liquid paint spraying in a rotating drum - by electrostatic spray guns on a flat conveyor - by hot coating in combination with a fluidized powder hopper All 3 processes allow the all-sided coating of work-pieces without hooks. In other words there are no hook contact points. Normally work-pieces must must be placed on a hook for coating. This is work- intensive and produces contact points, which can leed to corrosion and optical failures. |

|

|

With the drum process the parts are poured into a rotating drum , sprayed by a liquid paint and then dried.The drum process is suitable for rather thin decorative coatings such as zippers or pen sleeves. The coating thickness is in the range of 5 microns, only. Special paint is required for this process.

|

|

Powder coating on a flat belt is more used for functional purposes such as insulation and corrosion protection coatings, e.g. for car wheel balancing weights or inductive electronic components such as ferrite rings. The coating thickness is in the range of 80 . 100 microns. Mainly thermo-setting powders are used for this process.

|

|

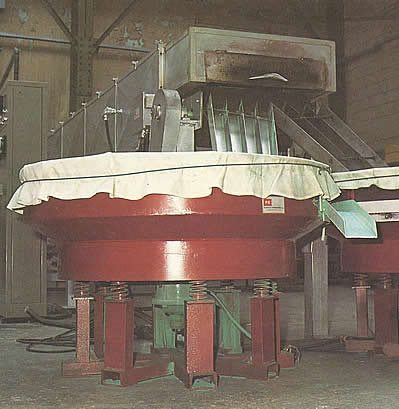

The hot coating process is mainly used for decorative / functional coatings in the lady underware and automotive industry. Mainly thermoplastic powders are used for this process. The coating thickness is in the range of 200 – 400 microns. |