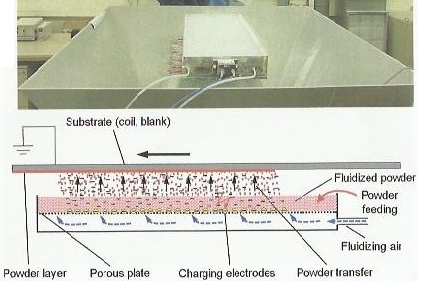

Gunless Powder Coating |

||||||||||||||||||||||||||||||

A new revolutionary process for coils and blanks ( pre-punched metallic sheet ) |

||||||||||||||||||||||||||||||

|

In most cases, powder coating is performed by electrostatic guns. If the desired coating capacity exeeeds e.g. 10 m2 per minute this may require between 10 – 20 guns depending on the geometrical shape of the work-piece. It is of course possible to use less guns, but, only by increasing the powder out-put and this will negatively affect quality and economy. This also requires large spray booths with high air volumes and high compressed air consumption. Especially when flat coating for e.g. coils and blanks. ( pre-punched od even pre-bent ) the guns blow against a large surface. This has a negative effect on the coating thickness tolerance and creates uncontrollable air circulations in the spray booth, particularly if the spray width is high. Almost 50 % of the coating output ( m2 per year ) for aluminium is produced on flat coating lines . Up to now, powder coatings have a limited deformability compared to thin liquid coatings . But, in this respect considerable progress has been made. Powders with Uretdione- cross linkers are very flexible and allow the deep drawing of thin metallic blanks after powder coating. These powders are TGIC -free. Curing is performed at very high speed with IR-heaters. Pre-Coating systems require much less energy and powder than post-coating systems . and the investment cost as well as maintenance cost are much less. |

||||||||||||||||||||||||||||||

|