ABOUT US / REFERENCES |

|

INNOVATION IN FINISHING SYSTEMS |

|

| Finishing Systems are complex and highly demanding. They comprise steel construction, metal sheet working, conveyor systems, process technology with all special disciplines like mechanics, pneumatics, electrics, electronics high voltage technology, physics, aerodynamics, chemistry a.s.o Here counts experience. The owner of the newly established Finishing Systems Consulting company has over 30 years of experience in this field. Users and system houses in the finishing business can benefit of this experience. |

|

| This experience he gained in a leading position with GEMA, a well-known manufacturer of electrostatic powder application systems and as former owner of SFB , a company who introduced for the first time in Europe the IR – curing technique as well as the powder coating of work pieces on a flat conveyor system. By this process punched blanks will be powder coated after bending and deep drawing. Twenty years ago, this was revolutionary. |

|

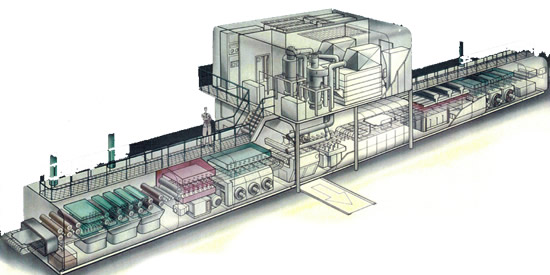

Miele Powder coating line for pre-punched blanks |

|

|

Also revolutionary was the development of a systems to powder coat very small parts of 10 – 100 mm on a flat conveyor system in hugh quantities on the entire surface. You may ask how this works?. Meanwhile over 26 lines of SFB installed all over the world powder coat almost 2 billions of small parts every year on a flat belt on all sides.. |

|

Small part powder coating system of SFB |

|

REFERENCES |

|

|

The owner of Finishing-System-Consulting can present the following references :

1. Managing of the development of a new generation of liquid –spray guns ( electrostatic guns, bells and disks ) at GEMA in Germany and Switzerland. 2. Support in development of the first Flat Coating Line according to the Pre-Coating- Process with powder at SFB in Germany. In this process the powder coated blanks ( pre-punched metal sheet ) are bent or even deep drawn after powder coating. This process is used amongst others by Miele for the powder coating of washing machines. 3. As owner of SFB company in Germany and Switzerland , responsible for development of a unique process for small work- pieces. Over 26 systems all over the world are meanwhile in operation, powder coating nearly 2 000 millions of small work-pieces in the automotive and electronics industry Tot he users belong companies like SIEMENS; PHIIPPS; HONEYWELL; EPCOS; TDK; HITACHI .

4. Development of a new concept for the Hot-Powder-Coating-Process for Starter Coils for the automotive Supplier Industry. In this process the work-pieces will be pre-heated and dipped into a fluidized powder hopper and subsequently post-heated.

|

|

We lead you to new ways in finishing technology. |